Table of Contents

- Module 1: Fundamentals of Lithium Polymer Batteries

- Module 2: Working Principles and Technical Specifications

- Module 3: Applications and Use Cases

- Consumer Electronics Applications

- Module 4: Safety Guidelines and Best Practices

- Updated UL 1642:2025 Safety Standards

- Module 5: Maintenance and Troubleshooting

- Optimal Charging Procedures

- Module 6: Selection Guide and Buying Considerations

- Key Specifications to Evaluate

Lithium Polymer Batteries: Complete 2025 Technical Guide | Safety, Applications & Selection

Module 1: Fundamentals of Lithium Polymer Batteries

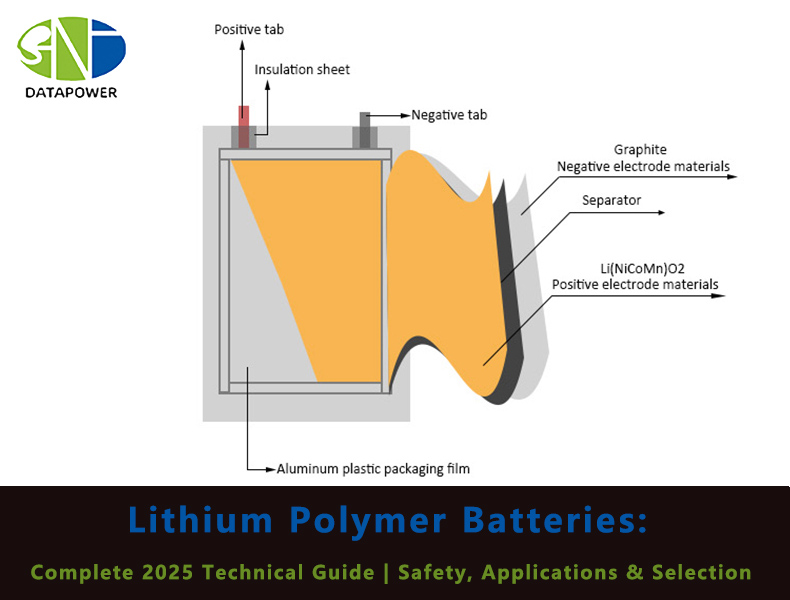

Definition and Basic Components

Lithium polymer batteries, commonly known as LiPo batteries, represent a significant advancement in rechargeable battery technology. Unlike traditional lithium-ion batteries with rigid casings, LiPo batteries feature a flexible polymer electrolyte housed in a pouch-like casing, allowing for versatile form factors and lighter weight.

The basic components of a LiPo battery include:

· Anode: Typically made of graphite

· Cathode: Composed of lithium cobalt oxide or similar lithium metal oxides

· Electrolyte: Polymer gel containing lithium salts

· Separator: Microporous membrane preventing electrode contact

· Casing: Flexible aluminum-plastic laminate pouch

Key Differences from Other Battery Types

Comparison with Lithium-ion Batteries

FeatureLiPo BatteriesLithium-ion BatteriesForm FactorFlexible, customizable shapesRigid cylindrical or prismaticWeight20-30% lighterHeavier due to rigid casingEnergy Density150-250 Wh/kg100-265 Wh/kgSafetyMore prone to physical damageMore resistant to physical damageCostGenerally higherMore cost-effective

Comparison with Lead-acid Batteries

FeatureLiPo BatteriesLead-acid BatteriesEnergy Density150-250 Wh/kg30-50 Wh/kgWeightSignificantly lighterVery heavyCycle Life300-500 cycles200-300 cyclesCharge Time1-2 hours8-16 hoursEnvironmental ImpactLower toxicityContains lead and sulfuric acid

Module 2: Working Principles and Technical Specifications

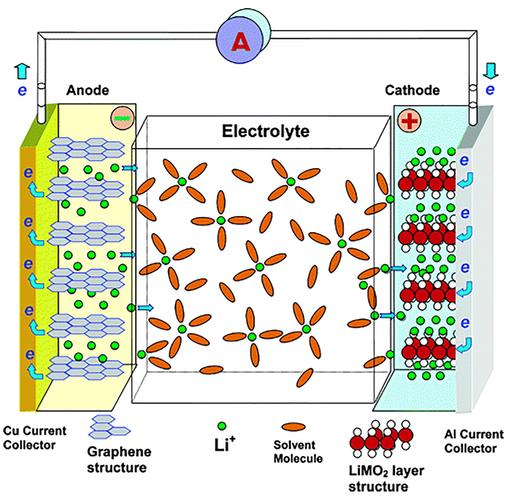

Electrochemical Processes Explained

LiPo batteries operate through electrochemical reactions where lithium ions move between the anode and cathode through the polymer electrolyte. During discharge:

1. Lithium ions move from the anode to the cathode

2. Electrons flow through the external circuit, providing power

3. The cathode accepts lithium ions and electrons

During charging, this process reverses, with lithium ions moving back to the anode.

Key Performance Metrics

Energy Density and Capacity

Modern LiPo batteries offer energy densities ranging from 150-250 Wh/kg, with some advanced prototypes reaching up to 300 Wh/kg. Capacity is typically measured in milliampere-hours (mAh) and varies significantly based on application requirements.

Charge/Discharge Rates (C-rates)

C-rate represents the rate at which a battery is charged or discharged relative to its maximum capacity. For example:

· 1C rate: Full charge or discharge in 1 hour

· 2C rate: Full charge or discharge in 30 minutes

· 0.5C rate: Full charge or discharge in 2 hours

Most LiPo batteries support continuous discharge rates of 20-30C, with some high-performance variants capable of bursts up to 60C.

Voltage Characteristics

LiPo batteries have a nominal voltage of 3.7V per cell, with operational ranges typically between:

· Fully charged: 4.2V per cell

· Nominal: 3.7V per cell

· Discharged: 3.0V per cell (should not be discharged below this point)

2025 Technology Innovations

Solid-state Electrolyte Advancements

The latest LiPo batteries incorporate solid-state electrolytes that significantly improve safety by eliminating flammable liquid components. These batteries offer:

· Enhanced safety: Reduced risk of thermal runaway

· Higher energy density: Up to 20% improvement over traditional LiPo

· Longer lifespan: Up to 1,000 charge cycles

· Wider temperature range: Operational from -30°C to 60°C

800V High-voltage Platform Technology

Leading manufacturers like Samsung SDI and LG Chem have introduced 800V high-voltage platforms that enable:

· Ultra-fast charging: 10-80% in just 15 minutes

· Reduced energy loss: Higher efficiency during power transfer

· Lighter wiring: Reduced copper requirements in electric vehicles

Fast-charging Breakthroughs

Huawei's 2025 breakthrough in "all-liquid cooling LiPo batteries" supports charging from 0-80% in just 10 minutes while maintaining battery longevity. This technology addresses one of the most significant limitations of electric vehicles and portable electronics.

Module 3: Applications and Use Cases

Consumer Electronics Applications

LiPo batteries dominate the consumer electronics market due to their lightweight and flexible form factors:

· Smartphones and tablets: Thin, high-capacity batteries

· Laptops: Custom-shaped batteries maximizing space utilization

· Wearable devices: Flexible batteries conforming to body contours

· Wireless earbuds: Ultra-compact, high-energy-density cells

Electric Vehicle and Transportation

The automotive industry increasingly adopts LiPo technology for:

· Electric vehicles: High energy density and fast charging capabilities

· Electric buses: Large-format batteries with extended range

· Electric aircraft: Lightweight solutions for aviation applications

· Electric scooters and bikes: Compact, high-performance batteries

Drone and RC Vehicle Applications

LiPo batteries are the preferred choice for drones and RC vehicles due to:

· High discharge rates: Supporting sudden power demands

· Lightweight construction: Maximizing flight time and performance

· Various form factors: Customizable shapes for different applications

· Quick recharge capabilities: Minimizing downtime between uses

Module 4: Safety Guidelines and Best Practices

Updated UL 1642:2025 Safety Standards

The latest UL 1642:2025 standards introduce critical safety requirements:

· Enhanced thermal testing: More rigorous temperature cycling tests

· Improved short circuit protection: Stricter criteria for internal protection circuits

· New transportation packaging: Mandatory fire-retardant packaging for shipping

· Environmental stress testing: Extended testing under extreme conditions

Common Safety Hazards and Prevention

Overcharging Protection Methods

Overcharging remains a significant risk factor for LiPo batteries. Prevention strategies include:

· Voltage monitoring: Automatic cutoff at 4.2V per cell

· Temperature sensors: Charging suspension above 45°C

· Balancing circuits: Ensuring all cells charge equally

· Timer protection: Automatic termination after maximum charging time

Thermal Runaway Prevention

Thermal runaway can lead to catastrophic battery failure. Prevention measures include:

· Current limiting: Preventing excessive charge/discharge currents

· Thermal fuses: Automatic circuit interruption at high temperatures

· Pressure relief vents: Controlled gas release during internal pressure buildup

· Flame-retardant additives: Electrolyte modifications to reduce flammability

Transportation and Storage Requirements

New Packaging Regulations for 2025

Updated transportation regulations mandate:

· Fire-resistant packaging: Class 4 materials for bulk shipments

· State of charge limits: Maximum 30% charge during transportation

· Damage inspection protocols: Pre-shipment visual and electrical testing

· Emergency response information: Detailed handling instructions for incidents

Environmental Storage Conditions

Optimal LiPo battery storage conditions include:

· Temperature range: 10-25°C (50-77°F)

· Humidity control: Below 65% relative humidity

· State of charge: 40-60% for long-term storage

· Storage duration: Regular inspection every 3-6 months

Module 5: Maintenance and Troubleshooting

Optimal Charging Procedures

Following proper charging procedures extends battery life and ensures safety:

1. Use appropriate chargers: LiPo-specific chargers with balancing capabilities

2. Charge at recommended rates: Typically 1C for standard charging

3. Monitor temperature: Stop charging if battery exceeds 45°C

4. Balance charge: Regular balancing to maintain cell voltage equality

5. Never leave unattended: Monitor charging process continuously

Storage Best Practices

Proper storage significantly impacts battery longevity:

· Partial charge: Store at 40-60% state of charge

· Cool environment: Maintain consistent temperature below 25°C

· Moisture protection: Store in dry conditions away from humidity

· Regular maintenance: Check voltage every 3 months and recharge if necessary

· Physical protection: Store in rigid containers to prevent physical damage

Common Issues and Solutions

Battery Swelling (Balloon Effect)

Battery swelling indicates gas generation due to electrolyte decomposition:

· Immediate action: Discontinue use and isolate from flammable materials

· Disposal: Follow local regulations for swollen battery disposal

· Prevention: Avoid overcharging, over-discharging, and high temperatures

· Replacement: Do not attempt to repair swollen batteries

Capacity Degradation

Gradual capacity loss is normal but can be minimized:

· Partial discharge cycles: Avoid regularly discharging below 20%

· Temperature management: Avoid extreme temperatures during use and charging

· Current limits: Operate within specified discharge rates

· Regular calibration: Full discharge/charge cycle every 10-20 uses

Module 6: Selection Guide and Buying Considerations

Key Specifications to Evaluate

When selecting LiPo batteries, consider these critical specifications:

· Capacity (mAh): Determines runtime

· Discharge rate (C): Must meet application requirements

· Voltage (cell count): Must match device requirements

· Dimensions and weight: Must fit within space constraints

· Connector type: Must be compatible with your device

· Brand reputation: Consider manufacturer quality and reliability

Brand Comparison and Reliability

Leading LiPo battery manufacturers offer different strengths:

ManufacturerStrengthsPopular ApplicationsSamsung SDIHigh energy density, reliabilityConsumer electronics, EVsLG ChemFast charging, longevityElectric vehicles, energy storagePanasonicConsistent performance, safetyMedical devices, aerospaceGens AceHigh discharge rates, valueRC vehicles, dronesTattuCustom configurations, specializedIndustrial applications, drones

Environmental Impact and Sustainability

Samsung SDI Eco-LiPo 95% Recyclable Materials

Samsung's 2025 Eco-LiPo initiative represents a significant sustainability breakthrough:

· 95% recyclable materials: Dramatically reduced environmental footprint

· Conflict-free sourcing: Ethical procurement of raw materials

· Reduced cobalt content: Lower reliance on controversial materials

· Extended lifespan: Up to 1,000 charge cycles reducing replacement frequency

Other Eco-friendly Innovations

Additional sustainability developments include:

· Bio-based polymer electrolytes: Derived from renewable resources

· Closed-loop recycling programs: Manufacturer take-back initiatives

· Reduced toxic components: Elimination of heavy metals and harmful chemicals

· Energy-efficient manufacturing: Lower carbon footprint production processes

Hey there,We are from Shenzhen Data Power Technology Ltd.

Shenzhen Data Power Technology Ltd. It is a manufacturer with 16 years of experience in lithium-ion manufacturing and research and development. "Get customized product solutions and save 30% on procurement costs."

CONTACT US NOW